The Impact of Vibration Machines on Bulk Solids Handling.

The mining, agricultural, pharmaceutical, and food processing sectors all rely heavily on the process of bulk solids handling. Maintaining smooth traffic of massive volumes of materials is crucial for maximum output. Vibration machines are one piece of technology that has significantly altered the handling of bulk materials. These clever tools employ vibrations to improve material flow, break up obstructions, and simplify processes. The advantages of vibration machines and their effects on industrial operations will be discussed in this article.

- Recognizing Vibration Equipment

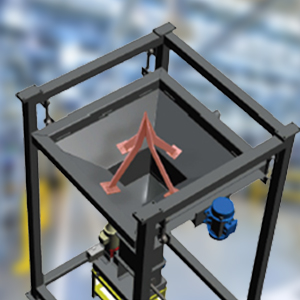

Bulk Bag Discharger may be moved from one site to another with the use of vibrating machines, also called vibratory feeders. These units have a trough or tube that oscillates at a predetermined frequency, therefore transferring the bulk material along its surface. The vibrations produced within the machine maintain a steady flow of materials, eliminating the problems of stagnation and obstructions that plague conventional handling techniques.

- Removing Impasses and Making Connections

Vibration machines' capacity to break up bridges and obstructions is a major benefit. Bin Activator Pune is indeed the best. Bulk sediments can build in traditional systems and get compacted, causing a blockage. Bulk Bag Unloaders are used to avoid this problem by continuously stirring the material, which dissolves any obstructions and allows the flow to proceed without interruption.

- Increased Productivity and Efficiency

Vibration devices greatly increase productivity and efficiency in bulk materials handling operations by preventing jams and blockages. Screw Bins are used widely. Reduced downtime and increased output are also benefits of a steady supply of raw materials. Industries that rely on the processing of huge amounts of commodities might benefit from this efficiency improvement, since it can lead to lower operational costs and higher profits.

- Modularity and adaptability

Because of its versatility, Vibrating Feeders are well-suited for processing a broad variety of bulk solids. These machines can process a wide variety of materials, including tiny powders, granules, pellets, and even abrasive ones. Vibrating Screens and frequency can be tailored to the properties of a given material for optimum efficiency.

- Special Care with Fragile Objects

Tube Vibrating Feeders are ideal for businesses like the food and pharmaceutical sectors where delicate materials need to be handled carefully. Materials are protected from excessive movement and degradation during transit thanks to the carefully calibrated vibrations.

- Low-energy consumption and hassle-free upkeep

Vibration machines have low power requirements because of their design. Compaction Tables are also outstanding. Due to the lack of moving parts like belts, pulleys, or chains, they are low-maintenance and cost-effective in the long run.

Conclusion

Bulk solids handling has been revolutionized by vibration machines, which provide a plethora of advantages that boost productivity and simplify production. Circular Screens has the finest results. Due to their ability to prevent bottlenecks, boost productivity, and safely handle sensitive chemicals, these devices have become standard equipment in many fields. The influence of Vibrating Tube Feeders Pune on bulk solids handling and their potential to revolutionize the way industries manage materials will only grow as technology progresses and new features and capabilities are added to these machines. Rectangular Vibrating Screen Pune is preferred by many people.